Digital Excellence – Jobflow Application

14 October 2022Jobflow is a managed digital end to end platform with mobile rugged tablet integration, health and safety requirement integration, automated GPS controlled data collection, and work item, plant and material management which is used by over 150 operatives and back of house staff on a daily basis. So far, we have recorded over 1,000,000 photos, 550,000 work items, reduced our paper trail by over 95% and achieved annual direct savings of over 1,000t of CO2, 8 million litres of water and 54t of solid waste. The application will soon allow full online access to clients to see live progress on all projects.

Soon after we decided to digitise our fire protection and concrete cutting divisions, we learned that the design and development of the application not only assisted the way we work, but it also defined and revolutionised the way we approach, plan, implement, quality control, manage and maintain our projects. Our clients have learned to appreciate the wealth of rich and timely information we provide as we work through the projects’ schedules which allows us to remain the leading Fire Protection and Concrete Cutting company in London. To our knowledge, Jobflow is the only fully integrated end-to-end Fire Protection and Concrete Cutting solution used in the construction sector. The following paragraphs explain some of the features and the rationale.

In recent years, the scale and volume of Kilnbridge’s Fire Protection and Concrete Cutting projects has increased rapidly, amplifying the operational challenges involved. This led to communication issues between site-based operatives and office-based staff and ultimately resource management difficulties and inaccuracies when producing operative job allocations, manual time sheets, payrolls, and client handover documents.

Kilnbridge realised the need for a bespoke end-to-end digital construction information system capable of incorporating all components of the project process whilst resolving these issues and building a digital culture. After reviewing and enhancing our existing policies and procedures to futureproof the system, we began working with a software development company. We produced Jobflow, a solution consisting of a mobile application that captures real-time information via tablets which can be used both online, offline and using back-office desktop application facilitating the operational, managerial and reporting features.

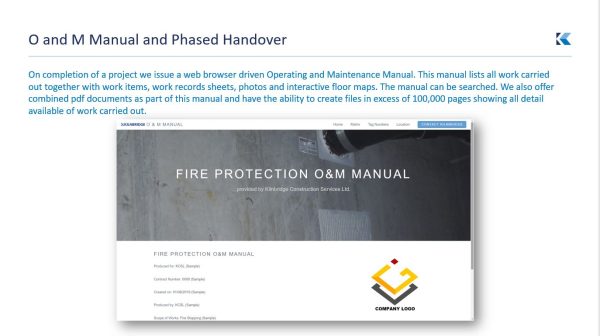

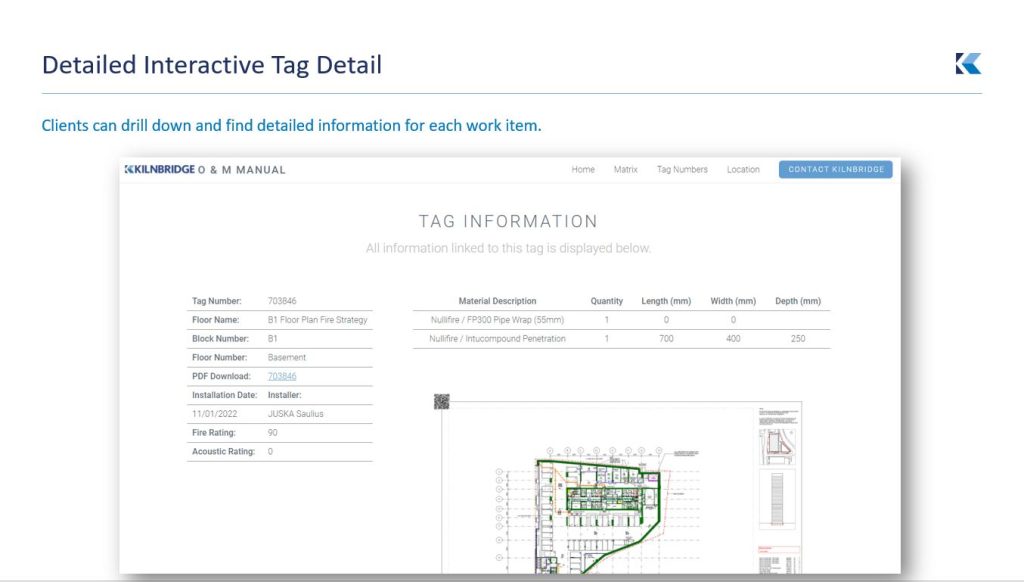

We designed the system with a multitude of benefits using an innovative digital construction approach. Jobflow’s key features include the creation and provision of Operating and Maintenance Manuals produced for clients when a project is finished. These contain overviews of all works completed, including thousands of tagged floorplans featuring the location, operatives and materials involved in works, progress photographs, work record sheets and technical documents. With the help of Jobflow we are now able to generate O&M manuals as part of individual project handover documents regularly accumulating more than 90,000 pages, which would traditionally/normally require a stack of paper 9 meters in height and 180 lever arch folders to be printed and stored.

There are too many features to describe all in detail, but here are some selected ones:

- Reduced stress and anxiety from operatives knowing where and when they must carry out clearly described work.

- Fully integrated into our payroll process reducing stress and time for head office staff.

- Increased Health and Safety by digitising over 20 HSEQ forms as well as integrated Nofity digital system for reporting near misses and observations.

- Easy oversight of scheduling 150+ operatives. Integrated holiday booking facility, operative certification management, and job allocation.

- Fully Integrated Vehicle Check process ensuring health and safety of our operatives and the general public.

- Full online client access to live project data, photos, floorplans, etc.

- Pre-work surveys of all work items increasing productivity, reducing the likelihood of incorrectly installed fire protection systems.

- Access to all data, 24/7 from all locations.

- Fully integrated user management to ensure the safety and security of digital resources.

- Integrated and managed information flow between Kilnbridge, operatives, clients via emails or the website.

- Fully integrated plant and material lists specific to each project reducing the risk of incorrect recording and installation.

- Pre-work site/work surveys where supervisors specify requirements for each individual work item making it easier for operatives to know what to install, which materials to use and when to carry out the work.

- Comprehensive and complete O&M manuals and handover documents with structured content such as photographs, tagged floorplans, Work Record Sheets, and meta data about material and plant used.

- Offline capability of tablet application in case no 4G signal is available.

- Integrated operative certification and skill resource database allowing us to easily schedule the most appropriate operative to the job.

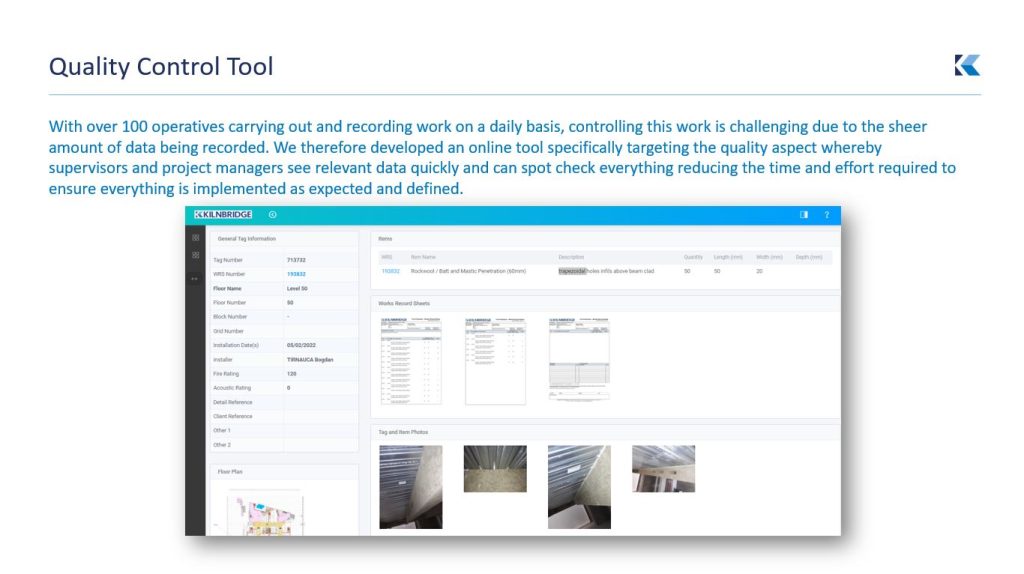

- All supervisors have access and need to sign off on site work carried out. A bespoke addition in terms of a quality control tool allows supervisors to see all work carried out for the past 7 days in form of photographs allowing them to easily spot mistakes.

- Improved transparency between client and Kilnbridge in terms of valuation of work carried out. Microsoft Excel integration and hyperlinks from each work item to resources such as material used, fire rating, acoustic rating, photographs and floorplans.

Some figures showing the scale and magnitude of this project not only for Kilnbridge but also for our clients and staff:

- Over 150 operatives use the tablet application on a daily basis.

- Over 50 office staff use the desktop application on a daily basis.

- All required HSEQ forms are digitised and can be filled in by operatives on site.

- Over 1 million photographs have been taken by operatives of work carried out.

- All clients have structured and interactive access to all project-related work items including photographs, floorplans, and Work Record Sheets.

- Daily automated emails to clients and operatives about work carried out.

- Significant environmental impact benefits following the digitisation and removal of over 95% of paper.

- Daily quality control applications for supervisors and managers to check operatives’ work.

- Offline capability when connectivity is not guaranteed.

- Collection of GPS coordinates and satellite-generated data.

- O&M Manuals produced for all projects of which some exceed 90,000 A4 pages.

- Valuation support for Kilnbridge and increased transparency for clients.

- Ongoing development and improvement of our processes and digitisation company-wide.

- Categories

- Awards

- Certifications & Accreditations

- Charity & Community

- Company News

- Health and Safety

- Innovation

- Project News

- Sustainability

- Recent News

- Kilnbridge Join Industry Partners at Canary Wharf Contractors Fund Charity Football Tournament

- Kilnbridge Triumphs at Final Dig Deeper Adventure Race

- Kilnbridge Wins Two International Green Apple Awards

- Kilnbridge Wins Concrete Specialist of the Year in the 2025 CN Specialist Awards

- Kilnbridge Wins 2025 Enginuity Large Employer Skills Champion Award